From idea to market launch

Pens manufactured via OEM production - step by step

From idea to market launch

Writing instruments manufactured via OEM production - step by step

IN SHORT

IN SHORT

- OEM enables manufacturing with full control over design, specifications, and intellectual property.

- Errors in planning or tolerances jeopardize the function of any writing instrument.

- Our 7-step plan takes you from concept and prototyping to series release – leading to a successful product launch.

- OEM enables manufacturing with full control over design, specifications, and intellectual property.

- Errors in planning or tolerances jeopardize the function of any writing instrument.

- Our 7-step plan takes you from concept and prototyping to series release – leading to a successful product launch.

OEM production of writing instruments is a complex process, demanding the highest standards of precision and reliability.

Basic pen functionalities can be compromised by unrealistic expectations or failure to adhere to the narrowest tolerances. A poor choice of production partner also poses a threat to the financial viability of the entire project.

In this article, we will navigate you step-by-step through the seven essential phases of OEM production for writing instruments.

Here you will gain exclusive insights into the industry’s production-related practices, enabling you to create your own implementation roadmap with this knowledge.

OEM production of writing instruments is a complex process, demanding the highest standards of precision and reliability.

Basic pen functionalities can be compromised by unrealistic expectations or failure to adhere to the narrowest tolerances. A poor choice of production partner also poses a threat to the financial viability of the entire project.

In this article, we will navigate you step-by-step through the seven essential phases of OEM production for writing instruments.

Here you will gain exclusive insights into the industry’s production-related practices, enabling you to create your own implementation roadmap with this knowledge.

Basics OEM Production

What is OEM?

Basics OEM Production

What is OEM?

OEM stands for Original Equipment Manufacturer.

In the context of writing instruments, this means: You commission a specialized partner to develop and manufacture your pen according to your exact specifications.

OEM stands for Original Equipment Manufacturer.

In the context of writing instruments, this means: You commission a specialized partner to develop and manufacture your pen according to your exact specifications.

OEM is the right choice when:

Plan for scaling

Whether you require high, consistent volumes or flexible adjustments, the OEM offers production flexibility without the need to tie up your own capital in manufacturing facilities.

Wish to consolidate resources

By outsourcing production, you can focus more intently on your core competencies, such as marketing, sales, and brand management.

Strive for strategic independence

Die Investition in eigene Werkzeuge sichert Ihnen das geistige Eigentum (IP) und schafft einen Wettbewerbsvorteil.

Seeking to rapidly enter global markets

The OEM’s expertise in all international certifications and standards saves you significant time and costs associated with market approval.

Require the highest precision and functionality

For complex technical challenges or the implementation of innovative designs, the OEM provides the necessary expertise and quality management, minimizing the risks and costs of errors (compared to in-house development).

OEM is the right choice when:

Plan for scaling

Whether you require high, consistent volumes or flexible adjustments, the OEM offers production flexibility without the need to tie up your own capital in manufacturing facilities.

Wish to consolidate resources

By outsourcing production, you can focus more intently on your core competencies, such as marketing, sales, and brand management.

Strive for strategic independence

Die Investition in eigene Werkzeuge sichert Ihnen das geistige Eigentum (IP) und schafft einen Wettbewerbsvorteil.

Seeking to rapidly enter global markets

The OEM’s expertise in all international certifications and standards saves you significant time and costs associated with market approval.

Require the highest precision and functionality

For complex technical challenges or the implementation of innovative designs, the OEM provides the necessary expertise and quality management, minimizing the risks and costs of errors (compared to in-house development).

From the idea to series production via OEM

Step 1:

Evaluate and Define the Idea

From the idea to series production via OEM

Step 1:

Evaluate and Define the Idea

Regardless of your company size and the origin of your idea:

You have decided on the realization.

With a clear vision for the design and function of your future writing instrument, the moment has arrived to transform this concept into a tangible product and kick-start its successful realization.

Expert Tip for Project Kick-Off

In the event of a desired resale, investments in capital, time and resources should naturally pay off.

Before initiating the next development stages and incurring higher expenses, critically evaluate your idea before the start with these 10 challenging questions:

Product

Does your writing instrument possess a unique selling point (USP) that incentivizes customers to make a purchase?

Market

Have you researched the target market and its prevailing regulations? Are the planned sales quantities aligned with the sales territory?

Price

Does your envisioned selling price match the target product quality?

Timing

Is the intended market launch date optimal with respect to competitors, seasonal cycles, or emerging trends?

Money

Is the funding for the full process—including contingencies for unexpected costs and launch delays—completely secured?

Protection

Do I possess the necessary clarity regarding patent risks and my own intellectual property (IP) protection requirements to prevent legal conflicts?

Sale

Is my intended distribution channel the most direct and efficient route to reach my target audience profitably?

Quantity

Is the product designed for scalability and does its configuration allow production to be easily and quickly expanded for high-volume manufacturing?

Vision

Do the characteristics of the pen match my marketing strategy (long-term market positioning vs. trend gadget/time-limited collector’s item)?

Values

Does the product truthfully reflect established values (such as sustainability) through its material selection and manufacturing process?

Important Note: This checklist is intended as a strategic compass, not a disqualifying factor. If not all questions can be answered right away, there is no cause for concern. An unsatisfactory response never indicates that the project is doomed to fail.

For us, Gutberlet Partners, this reveals clear opportunities: these are the points where we, as your partner, can proactively identify risks, offer support and optimize the process, ensuring your idea successfully reaches mass production.

Regardless of your company size and the origin of your idea:

You have decided on the realization.

With a clear vision for the design and function of your future writing instrument, the moment has arrived to transform this concept into a tangible product and kick-start its successful realization.

Expert Tip for Project Kick-Off

In the event of a desired resale, investments in capital, time and resources should naturally pay off.

Before initiating the next development stages and incurring higher expenses, critically evaluate your idea before the start with these 10 challenging questions:

Product

Does your writing instrument possess a unique selling point (USP) that incentivizes customers to make a purchase?

Market

Have you researched the target market and its prevailing regulations? Are the planned sales quantities aligned with the sales territory?

Price

Does your envisioned selling price match the target product quality?

Timing

Is the intended market launch date optimal with respect to competitors, seasonal cycles, or emerging trends?

Money

Is the funding for the full process—including contingencies for unexpected costs and launch delays—completely secured?

Protection

Do I possess the necessary clarity regarding patent risks and my own intellectual property (IP) protection requirements to prevent legal conflicts?

Sale

Is my intended distribution channel the most direct and efficient route to reach my target audience profitably?

Quantity

Is the product designed for scalability and does its configuration allow production to be easily and quickly expanded for high-volume manufacturing?

Vision

Do the characteristics of the pen match my marketing strategy (long-term market positioning vs. trend gadget/time-limited collector’s item)?

Values

Does the product truthfully reflect established values (such as sustainability) through its material selection and manufacturing process?

Important Note: This checklist is intended as a strategic compass, not a disqualifying factor. If not all questions can be answered right away, there is no cause for concern. An unsatisfactory response never indicates that the project is doomed to fail.

For us, Gutberlet Partners, this reveals clear opportunities: these are the points where we, as your partner, can proactively identify risks, offer support and optimize the process, ensuring your idea successfully reaches mass production.

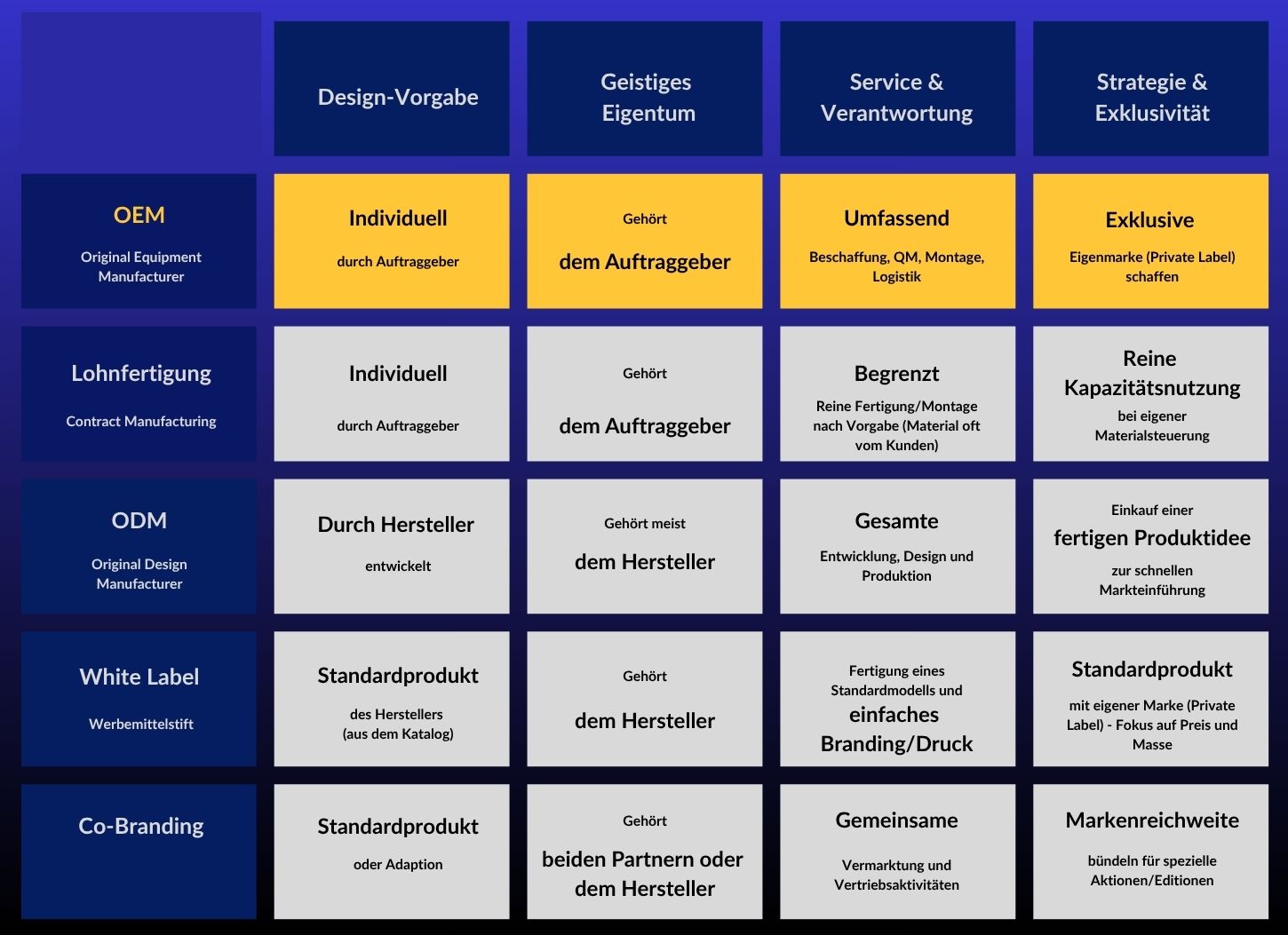

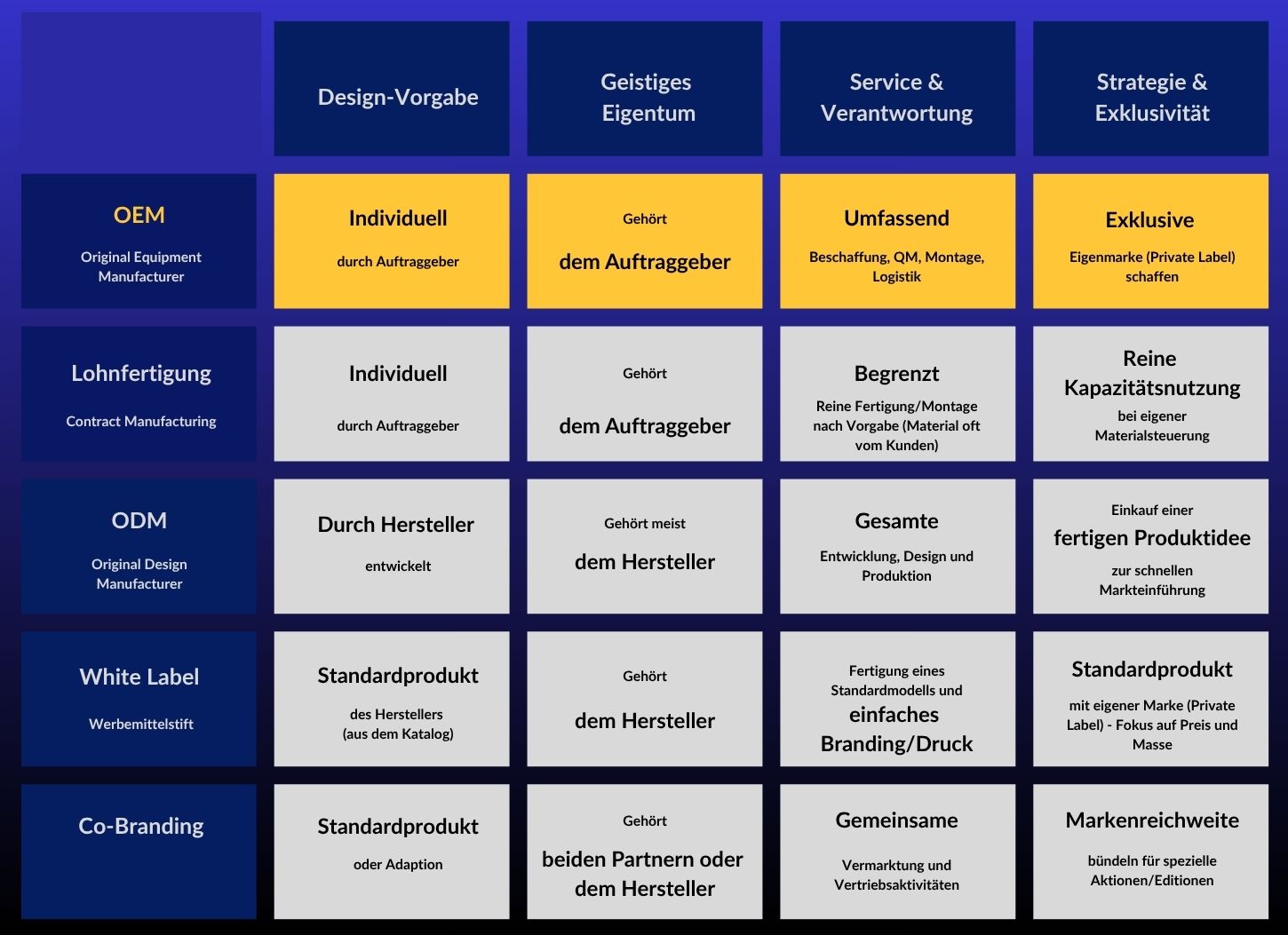

Distinction from Other Methods of External Manufacturing

An OEM develops exclusive proprietary brands according to the customer’s custom design specifications.

Contract Manufacturing provides production capacity exclusively for manufacturing custom products based on client specifications.

An ODM allows companies to source a complete product design, where the manufacturer retains responsibility for the design and development.

White Label (promotional pen) utilizes standard products for quick branding aimed at accessing price and mass markets.

Co-branding leverages the market reach of both partners through collaborative marketing activities.

Distinction from Other Methods of External Manufacturing

An OEM develops exclusive proprietary brands according to the customer’s custom design specifications.

Contract Manufacturing provides production capacity exclusively for manufacturing custom products based on client specifications.

An ODM allows companies to source a complete product design, where the manufacturer retains responsibility for the design and development.

White Label (promotional pen) utilizes standard products for quick branding aimed at accessing price and mass markets.

Co-branding leverages the market reach of both partners through collaborative marketing activities.

From the idea to series production via OEM

Step 2:

Documenting the Idea – Product Specification and Requirements Checklist

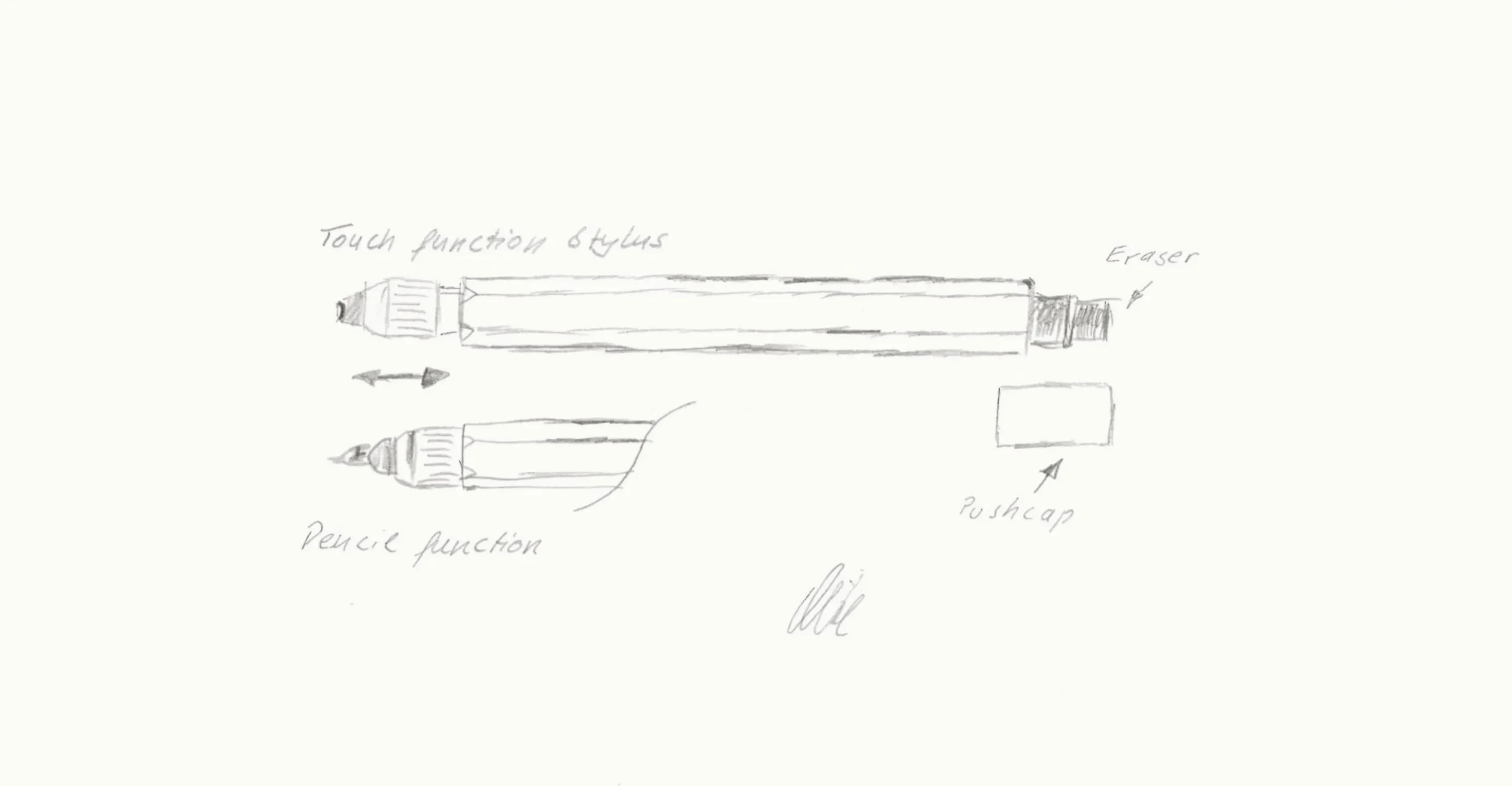

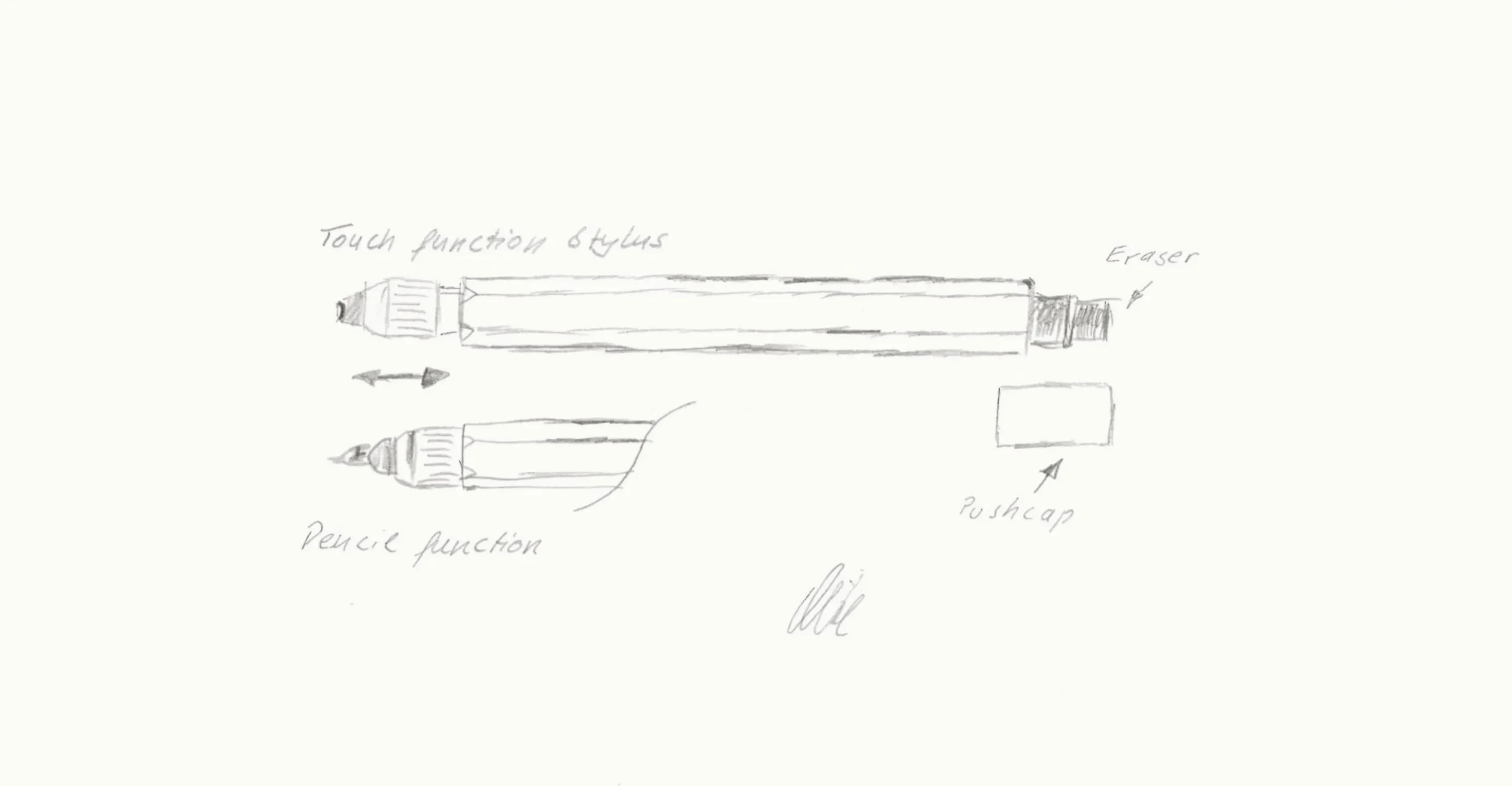

In order for third parties to unequivocally understand your concepts, the basic data of your writing instrument must be documented.

Precise technical sketches, any available 3D data and especially a detailed list of the desired product specifications are helpful for this purpose.

From the idea to series production via OEM

Step 2:

Documenting the Idea – Product Specification and Requirements Checklist

In order for third parties to unequivocally understand your concepts, the basic data of your writing instrument must be documented.

Precise technical sketches, any available 3D data and especially a detailed list of the desired product specifications are helpful for this purpose.

From the idea to series production via OEM

Schritt 3:

Den Richtigen FErtigungspartner finden

From the idea to series production via OEM

Schritt 3:

Find the right partner for manufacturing

Bringing a product to market always involves risk.

Manpower, time, and capital are always invested. Moreover, the idea often contains personal, conceptual value and passion that you naturally only want to place in trustworthy hands.

Keep the complexity in mind: Several partners are often involved in the production process.

The coordination and compatibility of the individual components must be guaranteed.

This is where we come in:

At Gutberlet Partners, we manage this complexity.

Thanks to our global network of material strategists, processing experts and finishing professionals, we can put together the optimum, quality-assured production alliance for your writing instrument project.

Critical Review Questions to Find a Trustworthy Production Partner:

- Has the partner been active in the market for a long time and do they have corresponding references that substantiate their expertise?

- Is the partner’s financial stability assured so they can maintain delivery capability, even when faced with substantial orders or unexpected challenges?

- Is communication ensured (e.g., in the required language), and does the partner act transparently during all steps?

- Has the total cost structure been broken down transparently (including unit price, tooling costs, and shipping costs)?

- Is the partner flexible enough to react quickly and solution-oriented to necessary adjustments?

- Does the partner have the required capacity to execute not only the initial run but also the planned volume scaling in a timely manner?

From the idea to series production via OEM

Step 4:

Start of the collaboration – consultation and feasibility

This phase is characterized by intensive consultation on writing technology, materials, processing and decoration as well as checking technical feasibility.

You will enter into an intensive exchange with an experienced partner. The aim is to optimize and flesh out your idea.

At the end of the process, your vision is in the best possible form – technically feasible, economically viable and organizationally efficient to implement.

Examples of questions that arise in this phase are

A. Technology, Precision and Function

- Does the selected interior mechanism integrate seamlessly into the overall design and the intended ergonomics of the writing instrument?

- Is the compatibility of all components reliably guaranteed over their entire lifespan?

- Are the dimensions and tolerance requirements in the technical drawings acceptable?

B. Aesthetics, Ergonomics and Durability

- Is the pen’s weight distribution optimized for ergonomic handling?

- Does the desired finishing technique ensure the best, long-lasting durability of the finish on the housing material?

- Are the chosen trim components compatible and are there alternatives or complementary features available to elevate the pen into a distinctive item?

C. Cost-Effectiveness and Value Proposition

- Can an alternative material or a more efficient processing method for the housing parts meet the optical requirements just as well, while noticeably reducing manufacturing costs?

- Is the use of standard components sufficient and economically sensible or does the unique nature of the pen require costly in-house development?

- Are the planned special features technically integrable and practical for the end user?

Bringing a product to market always involves risk.

Manpower, time, and capital are always invested. Moreover, the idea often contains personal, conceptual value and passion that you naturally only want to place in trustworthy hands.

Keep the complexity in mind: Several partners are often involved in the production process.

The coordination and compatibility of the individual components must be guaranteed.

This is where we come in:

At Gutberlet Partners, we manage this complexity.

Thanks to our global network of material strategists, processing experts and finishing professionals, we can put together the optimum, quality-assured production alliance for your writing instrument project.

Critical Review Questions to Find a Trustworthy Production Partner:

- Has the partner been active in the market for a long time and do they have corresponding references that substantiate their expertise?

- Is the partner’s financial stability assured so they can maintain delivery capability, even when faced with substantial orders or unexpected challenges?

- Is communication ensured (e.g., in the required language), and does the partner act transparently during all steps?

- Has the total cost structure been broken down transparently (including unit price, tooling costs, and shipping costs)?

- Is the partner flexible enough to react quickly and solution-oriented to necessary adjustments?

- Does the partner have the required capacity to execute not only the initial run but also the planned volume scaling in a timely manner?

Bringing a product to market always involves risk.

Manpower, time, and capital are always invested. Moreover, the idea often contains personal, conceptual value and passion that you naturally only want to place in trustworthy hands.

Keep the complexity in mind: Several partners are often involved in the production process.

The coordination and compatibility of the individual components must be guaranteed.

This is where we come in:

At Gutberlet Partners, we manage this complexity.

Thanks to our global network of material strategists, processing experts and finishing professionals, we can put together the optimum, quality-assured production alliance for your writing instrument project.

Critical Review Questions to Find a Trustworthy Production Partner:

- Has the partner been active in the market for a long time and do they have corresponding references that substantiate their expertise?

- Is the partner’s financial stability assured so they can maintain delivery capability, even when faced with substantial orders or unexpected challenges?

- Is communication ensured (e.g., in the required language), and does the partner act transparently during all steps?

- Has the total cost structure been broken down transparently (including unit price, tooling costs, and shipping costs)?

- Is the partner flexible enough to react quickly and solution-oriented to necessary adjustments?

- Does the partner have the required capacity to execute not only the initial run but also the planned volume scaling in a timely manner?

From the idea to series production via OEM

Step 4:

Start of the collaboration – consultation and feasibility

This phase is characterized by intensive consultation on writing technology, materials, processing and decoration as well as checking technical feasibility.

You will enter into an intensive exchange with an experienced partner. The aim is to optimize and flesh out your idea.

At the end of the process, your vision is in the best possible form – technically feasible, economically viable and organizationally efficient to implement.

Examples of questions that arise in this phase are

A. Technology, Precision and Function

- Does the selected interior mechanism integrate seamlessly into the overall design and the intended ergonomics of the writing instrument?

- Is the compatibility of all components reliably guaranteed over their entire lifespan?

- Are the dimensions and tolerance requirements in the technical drawings acceptable?

B. Aesthetics, Ergonomics and Durability

- Is the pen’s weight distribution optimized for ergonomic handling?

- Does the desired finishing technique ensure the best, long-lasting durability of the finish on the housing material?

- Are the chosen trim components compatible and are there alternatives or complementary features available to elevate the pen into a distinctive item?

C. Cost-Effectiveness and Value Proposition

- Can an alternative material or a more efficient processing method for the housing parts meet the optical requirements just as well, while noticeably reducing manufacturing costs?

- Is the use of standard components sufficient and economically sensible or does the unique nature of the pen require costly in-house development?

- Are the planned special features technically integrable and practical for the end user?

From the idea to series production via OEM

Step 5:

Prototype – Bringing the Idea to Life

From the idea to series production via OEM

Step 5:

Prototype – Bringing the Idea to Life

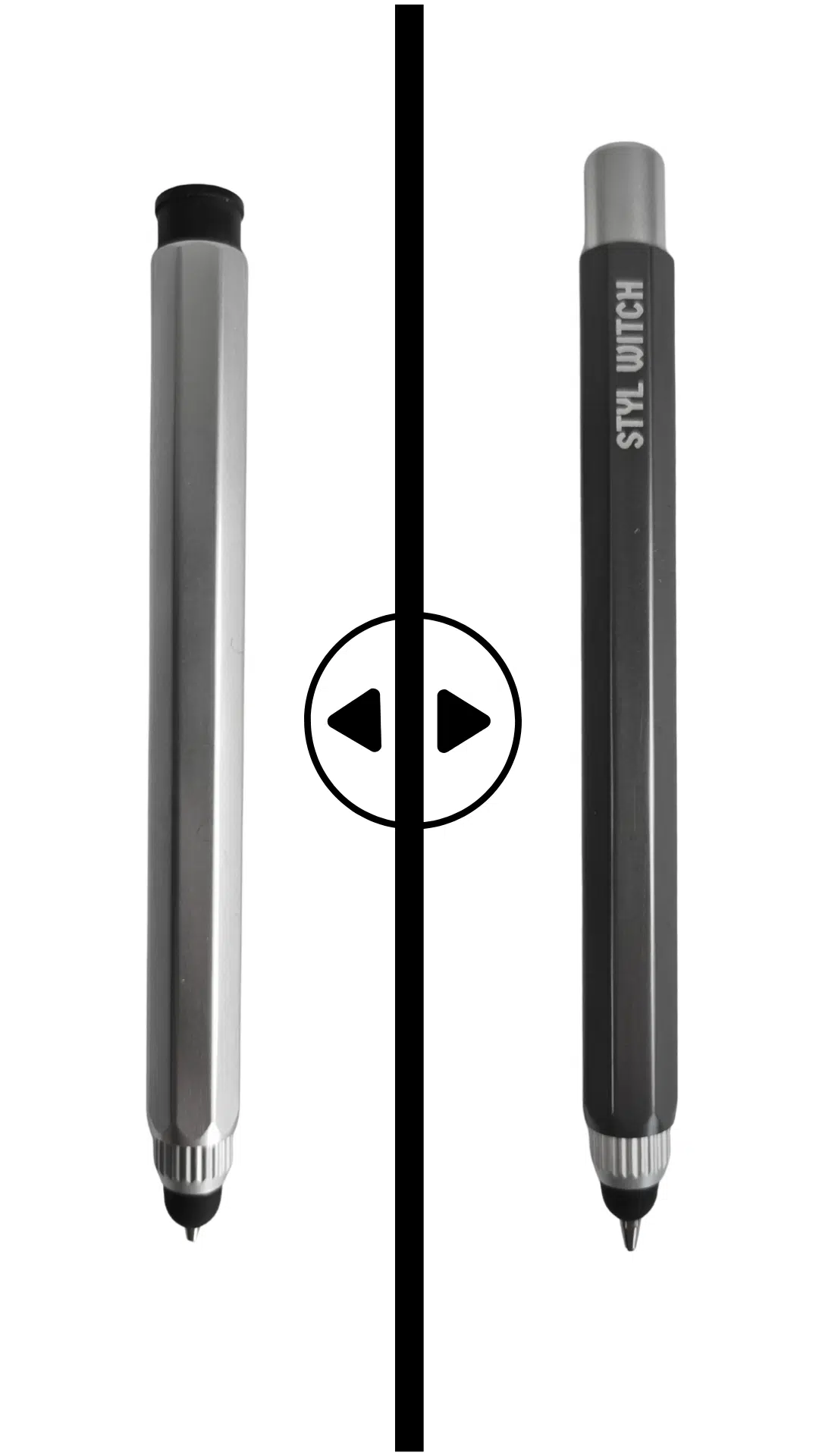

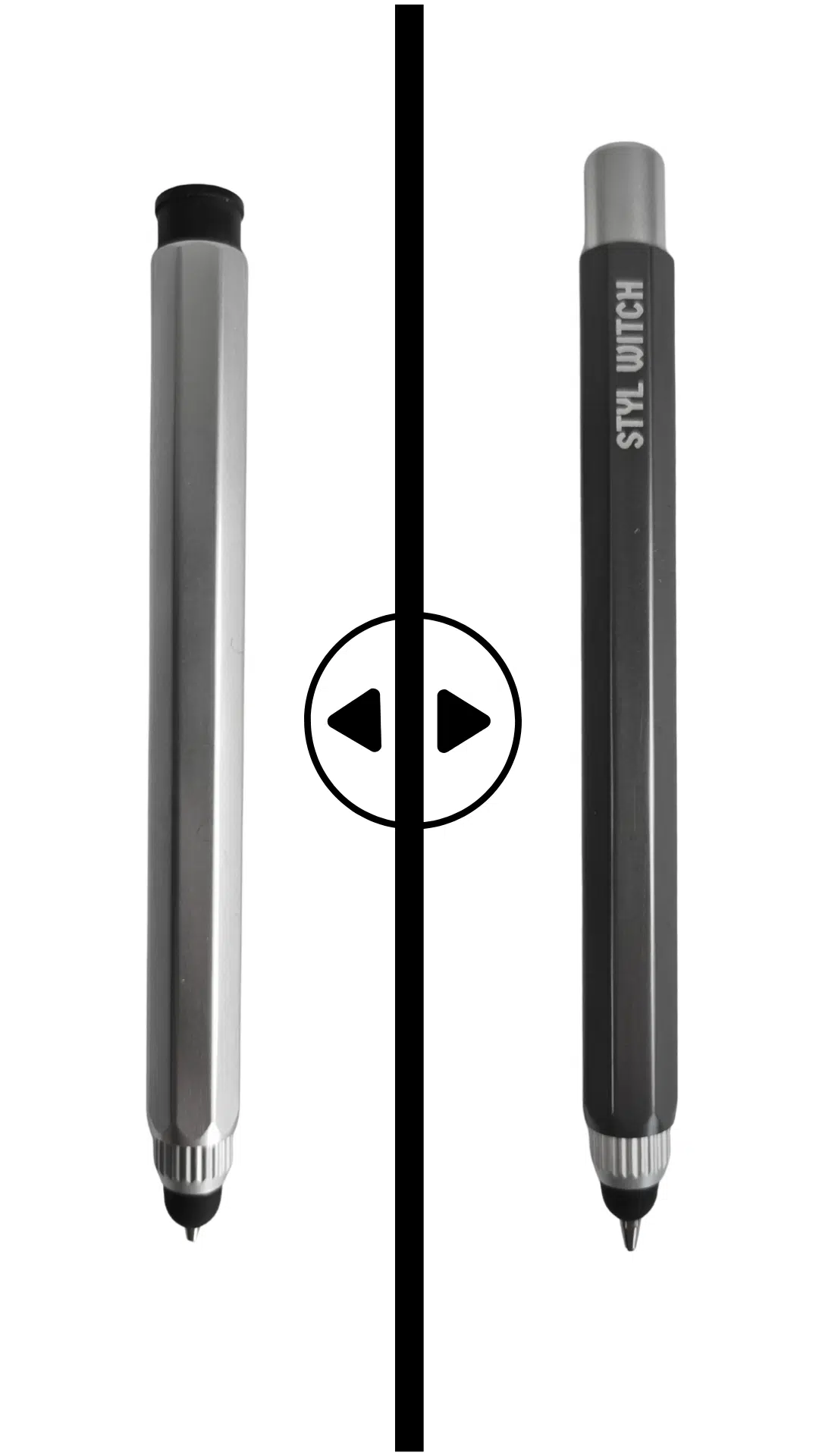

Using the final technical drawings and/or 3D models, the manufacturer creates an initial prototype. This phase typically avoids the expensive use of final production tools.

The prototype is used for physical visualization, verifying the ergonomics, haptics (feel), and fit of the components. It offers the ideal foundation for final refinements before commencing the creation of the definitive production tools (tooling).

Expert Tip on Prototyping

Even the slightest shift in tolerance during the production of a writing instrument can have extreme consequences for its functionality.

Lacking a full grasp of material characteristics, manufacturing capabilities and component compatibility—as well as validated quality testing procedures—you risk both functional failures and expensive unforeseen issues.

The picture shows a possible difference between the prototype (left) and the final writing instrument (right).

In the case of this example project, the following was added later on

- the housing color,

- a cap for the eraser was realized,

- adjusts the position of the internal pencil mechanism and

- a logo print is attached.

Using the final technical drawings and/or 3D models, the manufacturer creates an initial prototype. This phase typically avoids the expensive use of final production tools.

The prototype is used for physical visualization, verifying the ergonomics, haptics (feel), and fit of the components. It offers the ideal foundation for final refinements before commencing the creation of the definitive production tools (tooling).

Expert Tip on Prototyping

Even the slightest shift in tolerance during the production of a writing instrument can have extreme consequences for its functionality.

Lacking a full grasp of material characteristics, manufacturing capabilities and component compatibility—as well as validated quality testing procedures—you risk both functional failures and expensive unforeseen issues.

The picture shows a possible difference between the prototype (left) and the final writing instrument (right).

In the case of this example project, the following was added later on

- the housing color,

- a cap for the eraser was realized,

- adjusts the position of the internal pencil mechanism and

- a logo print is attached.

From the idea to series production via OEM

Step 6:

Test series and release samples – the dress rehearsal

From the idea to series production via OEM

Step 6:

Test series and release samples – the dress rehearsal

The test series now runs on the final tools, which were manufactured specifically for the product. Usually 10 to 20 samples are produced.

The purpose of this phase is to check exactly whether the technical drawings are converted into a product without errors and whether the tools work as intended.

This is the basis for consistent, high quality in subsequent series production – the dress rehearsal, so to speak.

This phase ends with the customer’s approval of the final sample.

It is often underestimated that undetected errors lead to high follow-up costs. An independent partner is now worth its weight in gold.

At Gutberlet Partners, we are experienced in evaluating these prototypes and know exactly what to look out for, what is tolerable and what needs to be adjusted. We intervene in the event of deviations and safeguard your interests on an objective, independent basis.

Expert tip: DAs independent, professional AuGE

The sign-off of the pilot run is the final checkpoint before the rollout.

The product must now demonstrate its readiness for volume manufacturing.

The final checks concentrate on:

- Funktion & Mechanik: Fehlerfreie Funktion der innenliegenden Mechanik

- Präzision: Perfekte Passgenauigkeit der Komponenten

- Performance: Indispensable writing qualities

- Quality: Proof of permanent load and long-term quality.

- Haptics & optics: final confirmation of haptics, weight balance and color accuracy

- Surface: Durability of the finish

- Process: Stability of the manufacturing process for mass production

The test series now runs on the final tools, which were manufactured specifically for the product. Usually 10 to 20 samples are produced.

The purpose of this phase is to check exactly whether the technical drawings are converted into a product without errors and whether the tools work as intended.

This is the basis for consistent, high quality in subsequent series production – the dress rehearsal, so to speak.

This phase ends with the customer’s approval of the final sample.

It is often underestimated that undetected errors lead to high follow-up costs. An independent partner is now worth its weight in gold.

At Gutberlet Partners, we are experienced in evaluating these prototypes and know exactly what to look out for, what is tolerable and what needs to be adjusted. We intervene in the event of deviations and safeguard your interests on an objective, independent basis.

Expert tip: DAs independent, professional AuGE

The sign-off of the pilot run is the final checkpoint before the rollout.

The product must now demonstrate its readiness for volume manufacturing.

The final checks concentrate on:

- Funktion & Mechanik: Fehlerfreie Funktion der innenliegenden Mechanik

- Präzision: Perfekte Passgenauigkeit der Komponenten

- Performance: Indispensable writing qualities

- Quality: Proof of permanent load and long-term quality.

- Haptics & optics: final confirmation of haptics, weight balance and color accuracy

- Surface: Durability of the finish

- Process: Stability of the manufacturing process for mass production

From the idea to series production via OEM

Step 7:

Series production, packaging and logistics

Finally, series production takes place.

Depending on requirements, not only the writing instruments are produced, but also their packaging. The logistics services are set in motion.

In the end, the customer receives a product that they can resell themselves or use as an exclusive advertising medium.

A good manufacturing partner is always available for questions, advice and service, even long after series production.

From the idea to series production via OEM

Step 7:

Series production, packaging and logistics

Finally, series production takes place.

Depending on requirements, not only the writing instruments are produced, but also their packaging. The logistics services are set in motion.

In the end, the customer receives a product that they can resell themselves or use as an exclusive advertising medium.

A good manufacturing partner is always available for questions, advice and service, even long after series production.

Case study

Individual pen production

Innovative writing instrument

Together with our customer Barbara Jöstlein Currie from Brass Witch, horn player at the Metropolitan Opera in New York, we developed an innovative writing instrument solution that today not only makes the lives of orchestral musicians around the world easier.

The starting point

Our customer approached us with the idea for a magnetic pen. However, not a single sketch existed yet – just a brilliant vision that emerged from her day-to-day work as a brass player.

Partnership-based project development

Our first step was to listen and understand the details of your foundation idea. This was followed by sketches, analysis and optimization of the idea as well as detailed reality checks hand in hand.

We managed the entire process chain: from commissioning the best specialists in our network to managing all the technical production and bureaucratic steps.

An all-round service for our customer, who was realizing such a project for the first time.

The result

Today, we are delighted to celebrate successes with her. The finished product represents the best possible combination of idea and technical feasibility.

Our partnership did not end with the delivery: even after production, we continue to support her with questions, industry insights and strategic developments.

Case study

Individual pen production

Innovative writing instrument

Together with our customer Barbara Jöstlein Currie from Brass Witch, horn player at the Metropolitan Opera in New York, we developed an innovative writing instrument solution that today not only makes the lives of orchestral musicians around the world easier.

The starting point

Our customer approached us with the idea for a magnetic pen. However, not a single sketch existed yet – just a brilliant vision that emerged from her day-to-day work as a brass player.

Partnership-based project development

Our first step was to listen and understand the details of your foundation idea. This was followed by sketches, analysis and optimization of the idea as well as detailed reality checks hand in hand. We managed the entire process chain: from commissioning the best specialists in our network to managing all the technical production and bureaucratic steps. An all-round service for our customer, who was realizing such a project for the first time.

The result

Today, we are delighted to celebrate successes with her. The finished product represents the best possible combination of idea and technical feasibility.

Our partnership did not end with the delivery: even after production, we continue to support her with questions, industry insights and strategic developments.

Summary:

OEM production requires maximum precision and in-depth specialist knowledge. The greatest risks arise from complex coordination and disregarding technical tolerances.

Gutberlet Partners offers you the independent expertise to master these challenges.

As a strategic navigator, we manage the entire supply chain through our network of experts. Our professional support – from consulting to delivery – safeguards your interests and systematically minimizes technical risks.